DCS Systems

More in need of a larger, more robust system. ICD can design and install the various parts needed for a DCS system.

DCS is more reliable due to the distribution of the control processing around nodes in the system. This mitigates a single processor failure. Only one section of the plant process is affected if a processor fails, as opposed to a failure of a central computer which would affect the whole process. This distribution of computing power local to the field Input/Output (I/O) connection racks also ensures fast controller processing times by removing possible network and central processing delays.

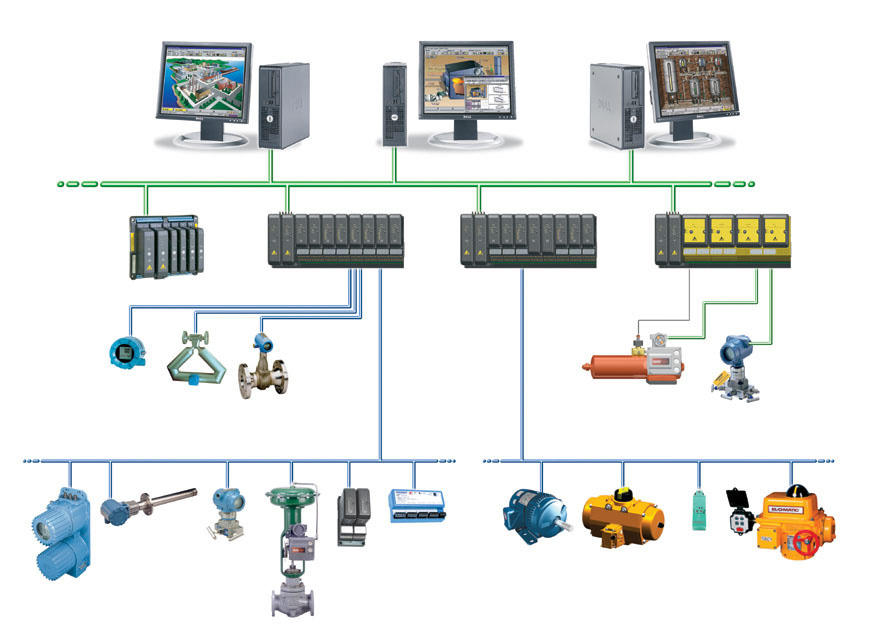

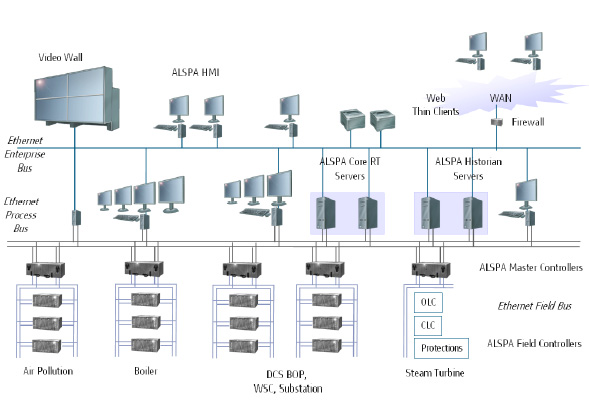

- Level 0 contains the field devices, such as flow and temperature sensors, and final control elements, such as control valves

- Level 1 contains the industrialized Input/Output (I/O) modules, and they are associated with distributed electronic processors.

- Level 2 contains the supervisory computers, which collect information from processor nodes on the system and provide the operator control screens.

- Level 3 is the production control level, which does not directly control the process but is concerned with monitoring production and monitoring targets

- Level 4 is the production scheduling level.